Catalogues and

technical guidelines

The extensive Blue Wave product range is divided into categories and separate catalogues based on industry.

- The marine category features UNF and metric wire fittings ranging from Ø 2 mm to Ø 26 mm/1/6″ to 1″, a rod system up to dash 60, rope fittings and various other marine related items.

- Our wire design system mainly features metric wire fittings from Ø 2.5 mm to Ø 36 mm, a tie-bar system as well as a range of small architecture fittings with reduced diameters.

- Wave Line contains a range of Ø 8 mm and 5/16″ standard swage, hand crimp and Lloyd’s certified swageless wire fittings for height safety.

- The Rope Line range features UHMWPE rope fittings up to Ø 16 mm and 5/8″ ropes which can be combined with other Blue Wave products or existing rigging.

We also do a lot of custom-made items.

Blue Wave production is ISO:9001:2015 certified.

Download the certificate below:

We issue the following certificates to order on demand:

| Certificate | Description |

|---|---|

| BWCC | Certificate of conformance |

| BW21 | 2.1 Certificate – declaration of compliance with the order |

| BW22 | 2.2 Test report – non specific |

| BW31 | 3.1 Inspection certificate – specific with destructive test |

To achieve maximum break load Blue Wave recommends pressing or swaging/rolling the terminals onto the wire ropes. Recommended machines for this purpose are e.g. presses from Talurit® and roller swaging machines from Wireteknik. Terminals from Blue Wave are also suitable for rotary hammer pressing.

Swaging ø12 mm terminals

There are 2 set of dies for 12 mm terminals: 12E and 12. 12E dies are used for swage fittings with an OD of ø20 mm before swaging. These dies are commonly used with 7 strand cables, such as 7×7 and 7×19, but can also be used with 1×19 cables.

Please note: Due to the strength of compacted cables, do not use 12E dies and end fittings.

The 12 dies are used for swage fittings with an OD of ø21,4mm before swaging.

For compacted and Dyform cables, Blue Wave always recommends using the 12 dies and swage fittings with OD of ø21,4 mm before swaging.

See the swaged dimension chart for further details to individual wire and terminal sizes.

| Wire Ø mm | Wire Ø inch | Inside diameter mm | Outside diameter mm (+/-0,10) | Depth mm (+/-1,5) | After swaging mm |

|---|---|---|---|---|---|

| 2 | 1/16” | 2,2 | 5,5 | 32 | 4,7 – 4,82 |

| 2,5 | 3/32” | 2,8 | 5,5 | 32 | 4,7 – 4,82 |

| 3 | – | 3,3 | 6,35 | 38 | 5,44 – 5,56 |

| 3,2 | 1/8” | 3,5 | 6,35 | 38 | 5,44 – 5,56 |

| 4 | 5/32” | 4,4 | 7,5 | 45 | 6,23 – 6,35 |

| 5 | 3/16” | 5,3 | 9 | 51 | 7,83 – 7,95 |

| 5,5 | 7/32” | 5,8 | 10,8 | 59 | 9,35 – 9,5 |

| 6 | – | 6,5 | 12,58 | 64 | 10,95 – 11,12 |

| 6,3 | 1/4” | 6,8 | 12,58 | 64 | 10,95 – 11,12 |

| 7 | 9/32” | 7,5 | 14,2 | 70 | 12,5 – 12,7 |

| 8 | 5/16” | 8,4 | 16 | 83 | 14,07 – 14,3 |

| 9,5 | 3/8” | 10 | 17,8 | 89 | 15,7 – 15,9 |

| 10 | – | 10,5 | 17,8 | 89 | 15,7 – 15,9 |

| 12 | – | 12,5 | 20 | 105 | 17,6 – 17,8 |

| 13 | 1/2” | 13,5 | 21,4 | 120 | 18,82 – 19,05 |

| 14 | – | 14,8 | 25 | 140 | 22 – 22,23 |

| 16 | 5/8” | 17 | 28 | 160 | 25,15 – 25,4 |

| 19 | 3/4” | 20 | 34,5 | 200 | 31,44 – 31,75 |

| 22 | 7/8” | 23,5 | 40,5 | 230 | 36,2 – 36,5 |

| 26 | 1” | 27,5 | 46 | 280 | 40,97 – 41,28 |

| 28 | 1 1/8” | 29,5 | 50 | 300 | 44 – 44,5 |

| 32 | 1 3/8” | 33,5 | 58 | 340 | 51 – 51,5 |

| 36 | 1 3/8” | 38 | 65 | 380 | 57 – 57,8 |

If the exact length of the final wire is unknown a good solution is to swage the wire onto one end while applying a swageless terminal on site at the other end.

Alternatively the Wire Design System offers a full range of small fittings that can be hand crimped onto the wires. With the small fittings 50% break load of the wire can be achieved.

Optimal break loads with Blue Wave rope fittings are achieved following the splice instruction given by the rope manufacturer in question. The rope fittings are designed to be stronger than the spliced rope.

When planning a wire construction the ultimate break load, as well as the work load, must be calculated as it will determine the minimum wire size and maybe the wire construction needed. Blue Wave’s fittings, unless otherwise stated, are constructed to meet 90% of the break load after termination on the wire ropes that are standard in the market.

PLEASE NOTE:

In order to guarantee safety in a wire construction you should calculate a safety factor of 2-3 on static constructions and a minimum of 5 on dynamic constructions. As a general rule working loads should never exceed 20% of the break loads stated in this catalogue.

| Thread size | Wire Ø meter | Wire Ø inch | Break load |

|---|---|---|---|

| M5 | 2 | – | 800 kg |

| M5 | 2,5 | – | 800 kg |

| M6 | 3 | – | 1.200 kg |

| M6 | – | 1/8” | 1.200 kg |

| 1/4” | – | 1/8” | 1.300 kg |

| 1/4” | 4 | 5/32” | 1.300 kg |

| 5/16” | 4 | 5/32” | 1.700 kg |

| 5/16” | 5 | 3/16” | 2.200 kg |

| M8 | 4 | 5/32” | 1.700 kg |

| M8 | 5 | 3/16” | 2.200 kg |

| 3/8” | 5 | 3/16” | 2.400 kg |

| 3/8” | 6 | – | 3.400 kg |

| 3/8” | – | 1/4” | 3.400 kg |

| M10 | 5 | 3/16” | 2.500 kg |

| M10 | 6 | – | 3.500 kg |

| 7/16” | 6 | – | 4.600 kg |

| 7/16” | 7 | 9/32” | 4.600 kg |

| M12 | 6 | – | 5.100 kg |

| M12 | 7 | 9/32” | 5.100 kg |

| M12 | 8 | 5/16” | 5.100 kg |

| 1/2” | 6 | – | 5.400 kg |

| 1/2” | – | 1/4” | 5.200 kg |

| 1/2” | 7 | 9/32” | 6.100 kg |

| 1/2” | 8 | 5/16” | 6.100 kg |

| M14 | 7 | 9/32” | 6.800 kg |

| M14 | 8 | 5/16” | 6.900 kg |

| 5/8” | 8 | 5/16” | 8.700 kg |

| 5/8” | – | 3/8” | 9.900 kg |

| 5/8” | 10 | – | 9.900 kg |

| M16 | 8 | 5/16” | 8.700 kg |

| M16 | 10 | – | 9.400 kg |

| 3/4” | – | 3/8” | 10.200 kg |

| 3/4” | 10 | – | 9.700 kg |

| 3/4” | 12 | – | 11.400 kg |

| 3/4” | – | 1/2” | 12.900 kg |

| M20 | 10 | – | 9.700 kg |

| M20 | 12 | – | 11.400 kg |

| M22 | 14 | – | 14.700 kg |

| 7/8” | 14 | – | 15.900 kg |

| M24 | 16 | 5/8” | 18.000 kg |

| 1” | 16 | 5/8” | 19.400 kg |

| M27 | 19 | 3/4” | 23.000 kg |

| M27 | 20 | – | 23.000 kg |

| 1 1/8” | 19 | 3/4” | 27.600 kg |

| M30 | 22 | 7/8” | 28.000 kg |

| 1 1/4” | 22 | 7/8” | 34.600 kg |

| 1 3/8” | 26 | 1” | 42.400 kg |

| M36 | 26 | 1” | 41.000 kg |

| 1 5/8” | 28 | 1 1/8” | 64.000 kg |

| M48 | 28 | 1 1/8” | 70.000 kg |

| M52 | 30 | – | 80.000 kg |

| M56 | 32 | – | 90.000 kg |

| M60 | 36 | – | 115.000 kg |

Always ensure that the wire is clean and has an evenly cut end.

Always use the correct size standard dies as recommended by the supplier. Correct wire attachment (termination) can only be achieved by firmly squeezing the material of the terminal into the strands of wire.

Blue Wave wire terminals correspond to the standard sizes and stainless materials used in the market. The terminals are produced so that a swage machine (e.g. from Wireteknik) will produce a swage within given tolerances in 1 (one) pass in the machine. When extremely compact strand ropes are used, 2 (two) passes in the same track could be needed to reach tolerances.

Additional passes should NOT be made.

Where markings are not possible, e.g. on the small terminals, the wire hole depth must be measured before swaging, not only to find the point to start the swaging but also to get the right length of the final wire including the fittings.

Caution: By swaging the terminals onto the wire, the shaft will get a little longer. As a rule of thumb the length will be prolonged by approximately the same amount of mm as the diameter of the wire in mm.

When tensioning a wire the wire will stretch and this needs to be taken into consideration during calculation.

Stretch is the degree of a material to which it is able to be lengthened by pulling and can be of two types:

- Structural of a permanent character. Caused when the initial load is applied.

- Elastic (ES) given by the applied load (kN), wire length (mm), modulus of elasticity of wire and it’s cross sectional area ( diameter2 x Pi/4 ). It is possible to calculate this value from the formula:

Elastic Strech – mm = Applied load (kN) x Length (mm)

e-modulus (kN/mm²) x cross section (mm²)

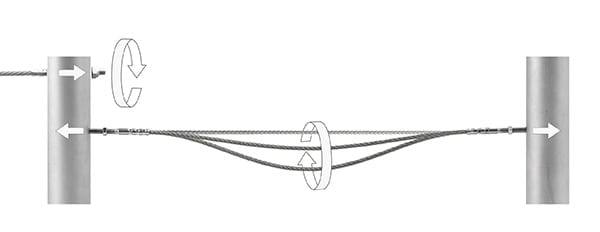

As well as serving as an attachment to a given construction, threaded terminals attached to both ends of a wire, can serve as a tensioner. Where tension cannot be applied to the thread via a nut at each end, the wire can be tensioned by use of e.g. right handed and left handed thread terminals at each end of the wire – by turning the whole wire tension will be applied.

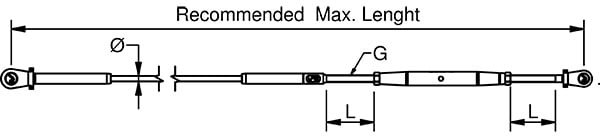

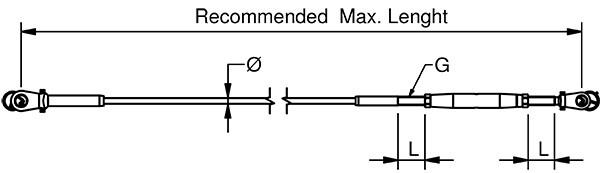

To ensure proper tension Blue Wave as a rule of thumb recommends the following maximum wire lengths.

Blue Wave fittings

| Wire Ø | G | L + L | RNL – 7 x 19 | RML – 7 x 7 | RML – 1 x 19 |

|---|---|---|---|---|---|

| 3 | M6 | 62 | 10M | 12M | 14M |

| 4 | M8 | 76 | 12M | 13M | 15M |

| 5 | M10 | 84 | 14M | 14M | 16M |

| 6 | M12 | 106 | 16M | 16M | 19M |

| 8 | M16 | 132 | 16M | 19M | 20M |

| 10 | M20 | 160 | 16M | 20M | 22M |

Blue Wave small fittings

| Wire Ø | G | L + L | RML – 7 x 19 | RML – 7 x 7 | RML – 1 x 19 |

|---|---|---|---|---|---|

| 3 | M5 | 36 | 6M | 10M | 12M |

| 4 | M6 | 44 | 8M | 10M | 14M |

| 5 | M6 | 44 | 10M | 12M | 14M |

| 6 | M8 | 46 | 10M | 12M | 14M |

Below is a table of the most frequently used types of stainless steel grades and their chemical composition.

| EN | AISI | C % | Cr % | Ni % | Mo % | N % | Si <% | Mn <% | S <% | P <% | PREN |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1.4301 | 304 | ≤0,07 | 17,5-19,5 | 8 – 10,5 | – | – | 1 | 2 | 0,015 | 0,045 | 17,5 |

| 1.4401 | 316 | ≤0,07 | 16,5 – 18,5 | 10 – 13 | 2 – 2,5 | – | 1 | 2 | 0,015 | 0,045 | 23,1 |

| 1.4404 | 316L | ≤0,03 | 16,5 – 18,5 | 10 – 13 | 2 – 2,5 | – | 1 | 2 | 0,015 | 0,045 | 23,1 |

| 1.4571 | 316TI | ≤0,08 | 16,5 – 18,5 | 10,5 – 13,5 | 2 – 2,5 | – | 1 | 2 | 0,015 | 0,045 | 23,1 |

| 1.4462 | 318LN | ≤0,03 | 21 -23 | 4,5 – 6,5 | 2,5 – 3,5 | 0,1 -0 | 1 | 2 | 0,015 | 0,045 | 30,9 |

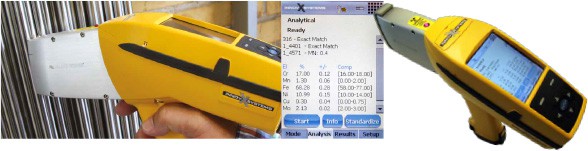

Blue Wave uses a X-ray device for the control of raw materials.

Maintaining stainless steel

Even though stainless-steel is corrosion resistant, fairly easy to maintain and thus well suited for maritime rigging, it still needs maintenance and in some parts of the world, more than in others!

The best way to do so is by rinsing frequently the stainless-steel fittings with fresh water, washing off salt and other particles.

Keeping the material clean will protect the fittings from being affected by pitting corrosion/running red due to salt and high temperature; especially when it hasn’t rained for some time!

Time is the magic word here – the longer time the salty liquid/spray can sit on the steel the more aggressive/the faster a reaction can be expected.

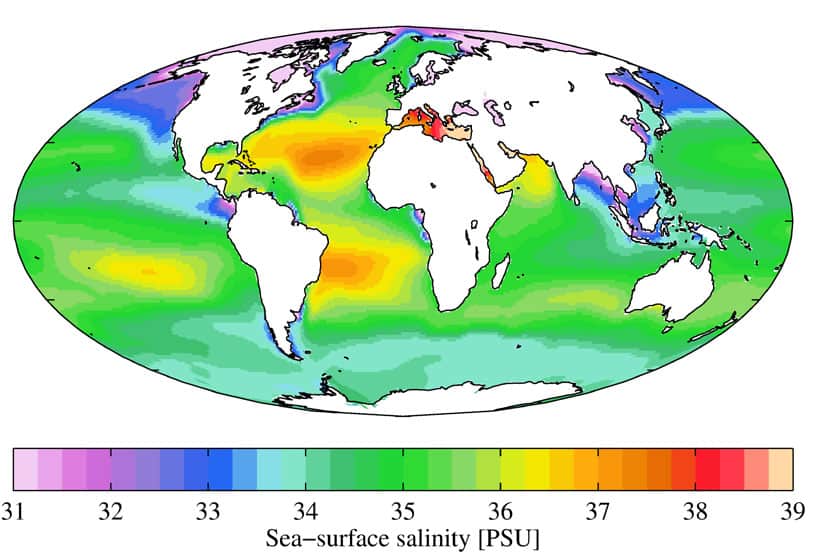

“Ocean salinity” is generally defined as the salt concentration (e.g., Sodium and Chloride) in sea water. It is measured in unit of PSU (Practical Salinity Unit), which is a unit based on the properties of sea water conductivity. It is equivalent to per thousand or (o/00) or to g/kg.”

One of the risk zones that can be mentioned, referring to above world map, is the Mediterranean Sea – this is due to temperature which easily can top 40 degrees and with high contain of chloride in the ocean.

Sailing the Mediterranean Sea, it is advisable to rinse the stainless-steel parts with fresh water as often as possible.

How to Keep Stainless Steel Stainless – Words of an Expert

Stainless steel is a wonderful material, and treated properly, it will stay bright and stainless forever. Sadly, natural saltwater is one of the most aggressive and corrosive media towards stainless steel, and even the ”acid resistant” 316L class requires a bit of maintenance in order to stay stainless.

In case of 316L above water, the main issue is time. Saltwater is very aggressive towards virtually any alloy, and the key issue is to keep the contact time as short as possible. In wet, temperate conditions, such as Scandinavia, the Canadian West Coast or the South Island of New Zealand, the all-too-common rain takes care of this, however, in warmer and drier conditions, such as Southern Europe and The Middle East, things are much different. Here, all saltwater sprayed onto the steel from below will tend to stick to the steel forever, with little chance of rain from above. Similar conditions are observed in dry season in the Caribbean, the tropical Pacific, or in South-East Asia. In the wet season, these places receive large amounts of rain, rendering any freshwater cleaning superfluous.

Very likely, the saltwater will cause superficial pitting corrosion, and although such attacks may not cause operational failure, it certainly looks unattractive and should be avoided. The best and cheapest way to avoid pitting corrosion is to keep the contact time low. Cleaning off the saltwater as quickly as possible keeps the contact time short, and the risk of corrosion correspondingly low. The more frequent the freshwater rinse, the better, and, presumably, a thorough rinse every fortnight should do the trick.

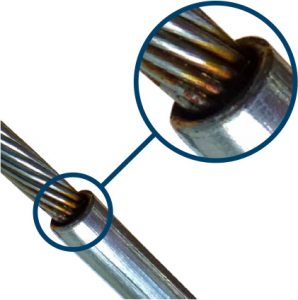

Be particularly aware that fittings below a braided steel cable are particularly prone to collecting saltwater, and so is the braided cable itself. Due to gravity, the upper fittings (pointing downwards) are less exposed to saltwater and may be rinsed less frequently.

If freshwater is not available, the second-best solution is to rinse with saltwater and dry the steel immediately afterwards. It is, still, preferable to use low-chloride water (i.e. freshwater) as often as possible.

Claus Qvist Jessen

MSc, chem. Eng. PhD

Damstahl a/s

Blue Wave High Quality Lubricant

To ensure good performance and long life Blue Wave next to general maintenance recommends that threads are regularly lubricated. We recommend a synthetic oil based lubricant with PTFE.

Synthetic oil based Lubricant with PTFE

The Blue Wave Lubricant contains PTFE micro powder, dispersed in synthetic base oil with anti-oxidation additives.

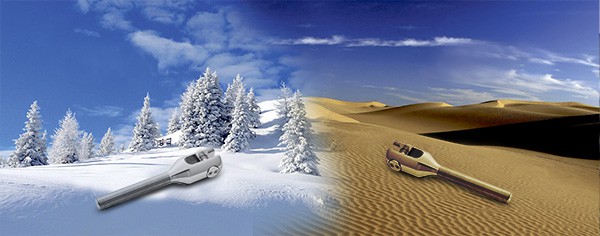

It is high effective lubricant, with long life properties, for use in metal to metal applications. Water repellent, do not soil, resists temperatures between – 50°C and +200°C. The Blue Wave Lubricant is non ageing and has extremely low friction and is used on the threads improving the performance. Whenever stainless steel threaded parts are screwed together it is always strongly recommended to lubricate the threads first, as this prevents the threads from jamming!

Supplied in tube with 5, 30 and 50 gr.

| ART. NO. | NET. WEIGHT | KG/100 |

|---|---|---|

| BWLUB1 | 50g | 5 |

| BWLUB2 | 30g | 3 |

| BWLUB3 | 5g | 0,5 |

| ART. NO. | NET. WEIGHT | KG/100 |

|---|---|---|

| SCTKIT | 6g | 6 |

Blue Wave products can be used in temperature range from -40°C to +100°C and briefly up to 200°C

Instructions for swageless wire fittings

The range of swageless wire terminals offer the possibility to attach wire to a terminal and achieve optimal wire break loads without use of machinery.

Blue Wave offers two main versions of these manual terminals, both can be combined with the standard range of products and assembly instructions can be found below:

- Swageless terminals with jaws – instructions (download pdf)

- Swageless terminals with cone – instructions (download pdf)

Instructions for rope end fittings

Blue Wave is ISO 9001:2015 certified and produces high quality stainless steel fittings and rigging screws ranging from ø 2 mm and up to ø 36 mm / 1/16” – 1-3/8” wire.

Serving various industries worldwide we have divided our range into four main groups and catalogues.

All our products are inspected and in-house tests are made to demand. Certificates are issued against order and destructive inspection tests can be made to order.

We believe that no market or customer is the same and rely on the expertise of our international partners. With them we serve and act to local market demands and encourage new ideas and solutions.

As a general assistance please find overview of our catalogues and general technical instructions below.